Item No.:Js-171 Payment:T/T&L/C Product origin:Hebei,China Shipping port:Tianjin Lead Time:about 30 days Price:29-39usd/sqm

Item No.:Js-171 Payment:T/T&L/C Product origin:Hebei,China Shipping port:Tianjin Lead Time:about 30 days Price:29-39usd/sqm

Chicken poultry farm house

Product Description

1. Type: construction building

2. Wide span: single span or multiple spans

3. Roof and wall option: steel sheet,EPS, fiber glass, rock wool or PU sandwich panel

4. Door and window PVC or aluminum alloy: sliding door or rolled door

5. Column and beam option: hot rolled or welded H section, I section; painting or galvanized

6. Purlin option: C-section or Z-section

7. Local climate: wind speed,snow load,rain quantity,earthquake grade

8. Usage: for the broiler or layer

9. Drawing: according to clients’ drawing,design as per clients’ dimension and requests

10. Package: naked loaded in shipping container or as per requests.

11. Equipment: according to the requirements of the customers

Specification:

| Use | Broiler or layer chicken house |

| Type | Closed type or open type |

| Material | H-beam/C-beam |

| Surface treatment | Galvanized/anti-rust paint |

| Equipment | As customer’s needs |

| Certification | CE iso9001 |

| MOQ | 600sqm |

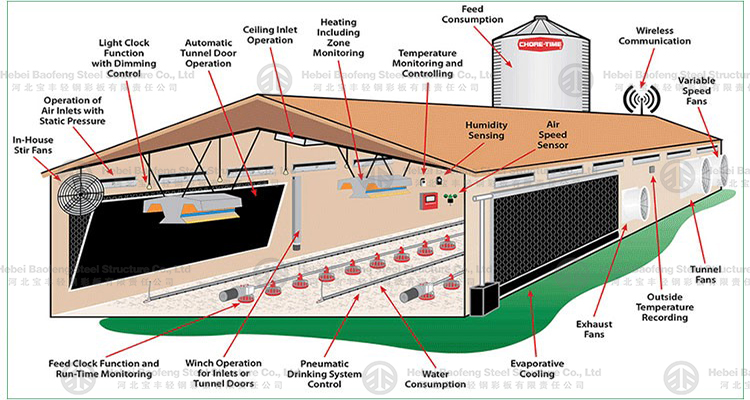

Cooling pad system

Evaporative cooling pad system works in the condition of negative pressure, the cooling pad has been installed in one side of the wall, the fans has been installed in the other side of the wall. When the air flows through the cooling pads, the water evaporation absorbs a lot amount of heat.

Normally the height of cooling pad is 1.5 m – 2.2 m, length is about 3 m, the area of cooling pad in chicken house is about 6-8 times than the fans.

Ventilation system

The main parts of ventilation system is the big fan and the small fan. They are controlled by the control system. The running qty of the fans was depended on the required temperature of the poultry house.

Normally, for about 200m2 area, it needs 1 big fan and 15-20m need a small fan, this is the standard to design the quantity of fans in the chicken house.

The insulation of steel structure chicken houses can be started from the following aspects:

1. Increase the thickness of thermal insulation material layer: Increasing the thickness of thermal insulation material layer on the walls and roofs of steel structure chicken houses can effectively increase the thermal insulation effect and reduce energy loss.

2. Installation of thermal insulation materials: Using polyurethane thermal insulation materials to insulate the chicken coop can not only mitigate the impact of internal and external temperature differences, but also effectively prevent the rapid loss of temperature.

3. Install ventilation and heat insulation equipment according to the appropriate proportion: Proper ventilation and heat insulation equipment can effectively control the temperature of the chicken house, ensure the air circulation and fresh air supply inside the chicken house.

4. Insulation at the top of the chicken house: The top is the key point of heat leakage in the chicken house, so it is necessary to focus on insulation work to ensure continuous and stable temperature inside the chicken house.

If you need it, please answer the following questions so that we can serve you in time:

1>what about the length width height you need build?

2>Or how many chickens do you want to raise?boiler or layer?

3>Do you have a drawing of your chicken house?

4>Where is your project site?